FFS Interpolator

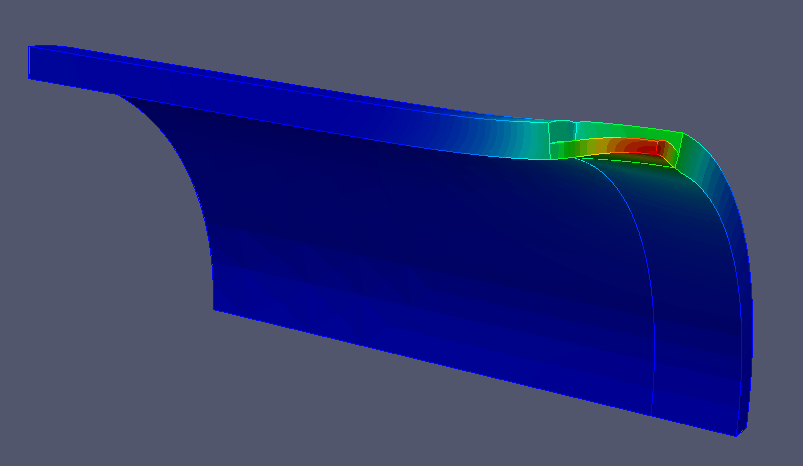

Improve on API 579 Level 1 or 2 It’s been a while between posts, so let me say that I haven’t been completely idle – I’ve been cooking up a new web-based calculation app for engineers dealing with corrosion defects. On the surface, this application looks similar to the API 579 Level 1 assessment for … Read more