In Part 2 of this interview, welding engineer and futurist Niekie Jooste addresses a wide range of future-facing topics including Education, Resource-based companies/countries, Blockchain, QA/QC, Google, Science fiction and career planning.

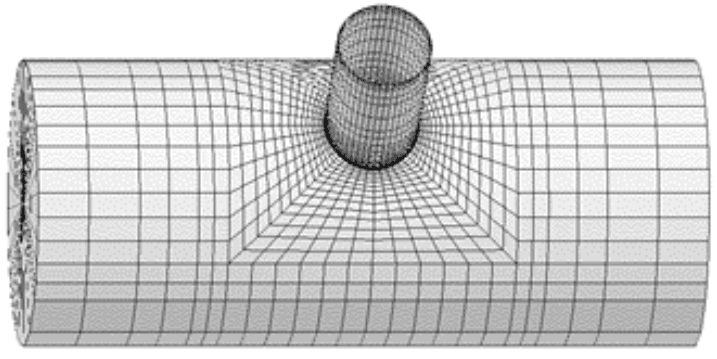

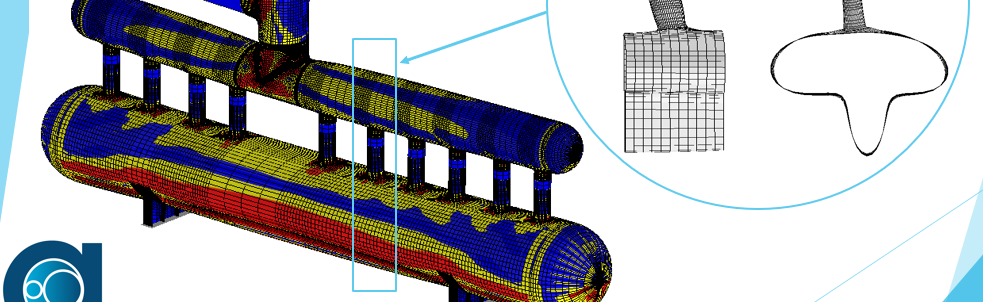

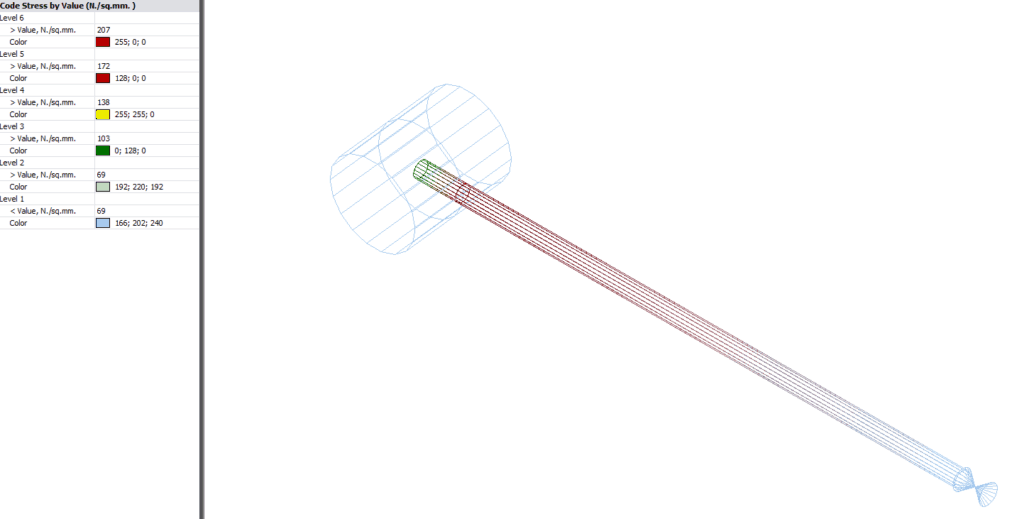

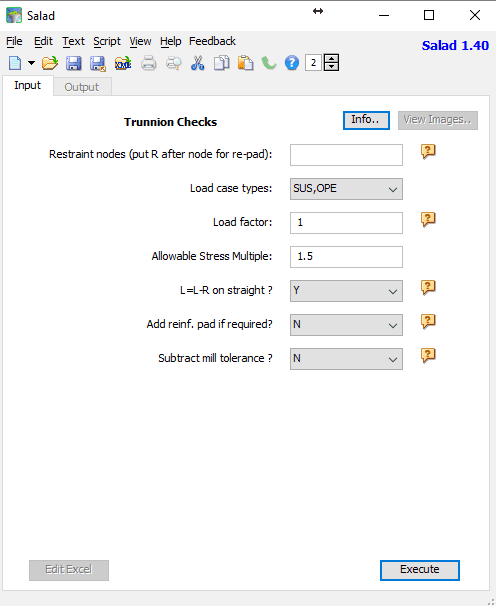

Martin helps clients keep on top of their pressure piping and equipment integrity issues via stress analysis, FEA and fitness for service. He is the author of various articles, an ASME paper and software including the Salad post-processor for CAESAR II and web apps on this site. In a former life he played whizzbang lead guitar, but now he just plays old albums..